The function of the actuator is to move something. In hydraulic, an actuator converts the hydraulic energy into mechanical energy. You may already have some knowledge about the subject, but this chapter will help consolidate your knowledge and fill if there are any gaps.

Content

- The basic function of actuators.

- Types of actuators.

- Hydraulic cylinder types and their applications.

- Types of hydraulic motors and their applications.

The basic function of the actuator

The actuator is a converter or drives element in a hydraulic system. It is the component that converts hydraulic energy into mechanical energy. In any hydraulic system, our ultimate intention is to generate force and displacement at the user end. Hence, we use actuators in the hydraulic system. Let’s see different types of actuators.

Hydraulic actuator Characteristics

The characteristic of the hydraulic actuator or cylinder is to transmit the large force. But this has the limitation that the force can transmit only in its effective length and linear motion. Depending on its construction type, the hydraulic cylinders can transmit forces either in one or two directions.

People also read “Formula for converting cc/rev to LPM.“

Types of Actuator

- Linear Motion Actuator or Cylinder

- Rotary Motion Actuator or Motor

Linear Motion Actuator or Cylinder

A hydraulic cylinder or linear actuator is the component that converts hydraulic energy into linear motion (mechanical energy). A hydraulic cylinder or linear actuator works on the displacement principle. They convert the flow directed into the cylinder chamber into linear motion.

Hydraulic Actuator types and their application

- Single Acting Hydraulic Cylinder

- Double Acting Hydraulic Cylinder

- Special Design Cylinder

Depending on the direction, a hydraulic cylinder or linear actuator can transmit force in one direction or two directions. If the force can transmit only in one direction then it is a Single-acting cylinder. Similarly, if the force can transmit in both the directions (i.e. to and fro motion) then it is a Double-acting cylinder.

The function of the Single Acting Actuator or Cylinder

In a single-acting cylinder, the hydraulic pressure built up only on one side of the piston or piston rod and converted into mechanical force. With pressure, the piston rod can thus extend or retract only in one direction. That is why it is referred to as a single-acting cylinder.

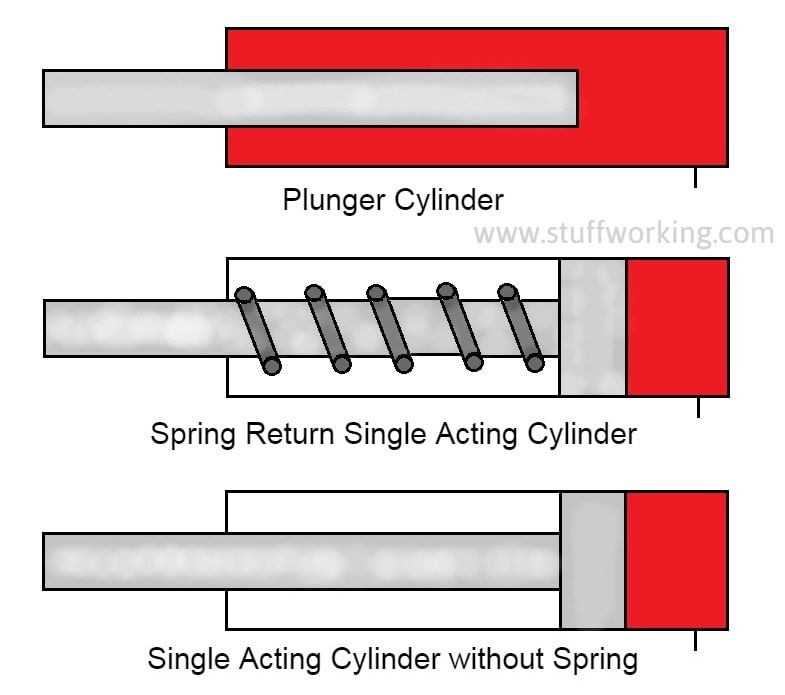

Types of single acting cylinder or actuator

- Plunger cylinder: The plunger cylinder is sometimes called the trunk piston cylinder. Here the piston rod is used as a piston. For example, hydraulic jack. In a hydraulic jack pressurized fluid pushes the plunger out. But the piston retracts again under its curb weight after the pump is switched off.

- Spring return hydraulic cylinder: The cylinder with return spring, the spring force pushes the piston back after the pump is switched off. although, Most small cylinders use a spring return mechanism. This type of single-acting cylinder can be used in a horizontal position where the piston cannot move from its weight to its initial position after the pump is stopped. The rod side spring presses the piston back when the pressure drops. Spring returns can be either push-type or pull-type depending on the cylinder design.

- Single-acting cylinder without spring: The function of a single-acting cylinder without a spring is similar to a plunger cylinder. After the pump is stopped the piston returns to its original position due to its own weight or external forces.

Double Acting Actuator cylinder

In contrast to single-acting cylinders, double-acting cylinders have two effective piston surfaces (piston side and Piston-rod side). Therefore, they can extend as well as retract using hydraulic pressure.

Type of double acting cylinder

- Differential double-acting cylinder

- Synchronizing double-acting cylinder.

Differential double acting cylinder

In a differential double-acting cylinder, the two effective areas of the piston are of different sizes. Due to this difference in the piston area, there is also a difference in the force transmission and speed of the cylinder. In the above figure, when the piston extends, it can transfer larger force with lower speed than retraction. Hence, it is a differential double-acting cylinder. It is a very common and mostly used cylinder.

Synchronizing double-acting cylinder.

In a synchronizing double acting cylinder, there is the piston rod on both sides as shown above. The effective areas of the piston are identical on both sides and hence, the same speed and force transmission when the same working pressure applied during extension and retraction. Thus, for constant flow, piston stroke speed is identical in both directions.

Special Design Cylinder

- Telescopic cylinder

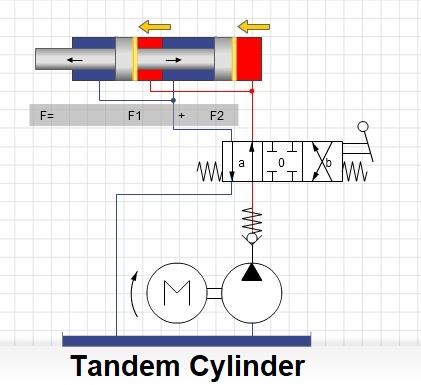

- Tandem cylinder

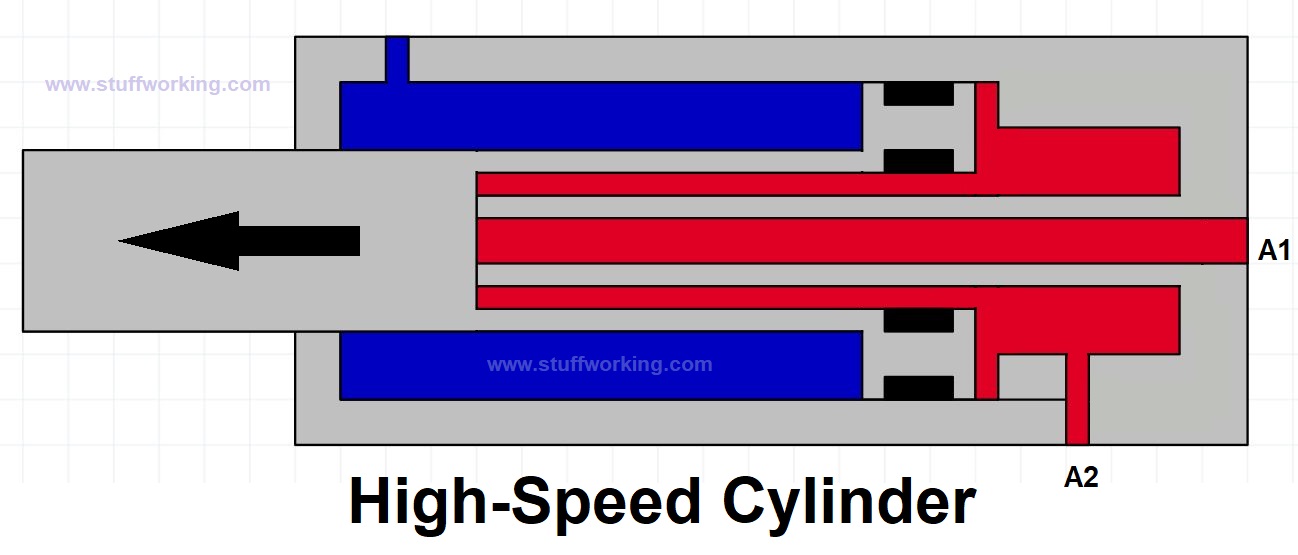

- High-speed cylinder

Hydraulic Rotary Actuator or Hydraulic Motor

The function of a hydraulic motor or rotary actuator is to converts the hydraulic energy into rotary motion (mechanical energy). The working principle is the same as a hydraulic cylinder (i.e. Displacement principle). But the difference is that the hydraulic motor can give continue rotation regardless of stroke length.

Types of Hydraulic motor

- Fix displacement motor

- variable displacement motor

The hydraulic motor comes in very different designs. The selection of a motor depends on the purpose of the motor. Before selecting a hydraulic motor, the manufacturer’s datasheet must always be observed. A hydraulic motor can be a fixed displacement motor or a variable displacement motor. For example, external gear motor, internal gear motor, gerotor, vane motor are fixed displacement type. Whereas radial piston motor or axial piston motor can be fixed or variable both.

Difference Between Hydraulic Cylinder and Motor

Related Article

- Pressure reducing valve and pressure relief valve

- Hydraulic accumulator working principle

- Hydraulic Tank Design, Task & Type

Reference: Wikipedia, and author own experience.