Last updated: August 24, 2020

Most of us are very familiar with the pressure relief valve and pressure reducing valve. Both valves control the pressure in the hydraulic system. Since both are pressure controlling device still both are different from each other. Therefore, we will learn in this article how they differ with each other, where it can be used, and their construction. Also, we will see some special-purpose valves.

Pressure relief valve

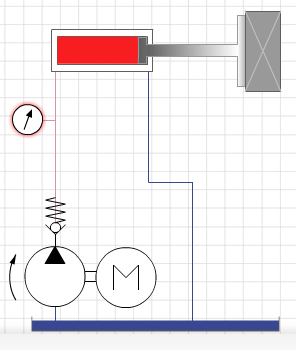

Consider a simple hydraulic system without a relief valve for instance.

When the pump starts and does the work by lifting the load up to its maximum limit. But when it reaches its limit what will happen? The pump is still running and tries harder to push more oil in the system and ultimately pressure will increase tremendously and damage the weaker component. Therefore we need something which will limit the pressure in the system. This component is a pressure relief valve.

Pressure relief valve: A pressure relief valve is a hydraulic component that provides safety to the hydraulic system from excessive pressure. This is normally closed but when the pressure in the hydraulic system increase beyond the set limit of a pressure relief valve, it opens the path and allows hydraulic oil to flow into the tank. In this way, it releases the excessive pressure from the system and provides protection. As soon as pressure reduces in the system, the pressure relief valve comes in the initial position and closes the open path again.

As shown above, an arrow shows the closed path for hydraulic fluid and there is also spring tension which forces the relief valve to remain closed. But when the pressure in the hydraulic system is enough or more than relief valve spring tension, a pilot line will push the arrow against the spring tension and open the path. In this way, the pressure is relieved from the system and save the components.

Click to learn Industrial Hydraulic Symbols.

Construction of pressure relief valve

A pressure relief valve can be designed in many more ways but, here it is the most common type of pressure relief valve. It consists of two passages one is

As in above figure 4, you can see there is a valve seat which is normally closing the inlet and seat holder is forced against a spring. At the top, there is a screw which will set the spring tension or in other word set the pressure of the relief valve. Usually, the screw is protected with a cap so, the unauthorized person can not change the pressure setting and also it protects the screw from rusting.

Pressure Reducing Valve

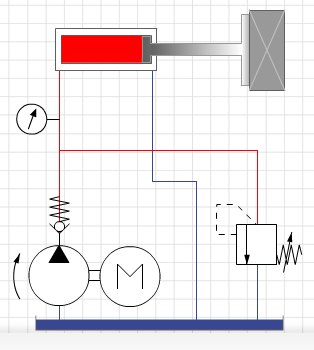

Pressure reduction valves are used to limit the hydraulic pressure in a system. However, instead of reducing inlet pressure, they reduce the outlet pressure. It divides a hydraulic system into different sub-systems. For Example, If a hydraulic system there are numbers of operations, and each has its own capacity. As per every hydraulic component, there may be a different pressure requirement but with only one pump this cannot be achieved but with the use of pressure reducing valve it can easily achieve.

Pressure reducing valve is normally open valve and it allows the pressurized fluid to flow but when the pressure at the output of the valve is more than the valve pressure setting, a pilot pressure pushes the arrow down and the path will close. The valve will not allow pressurized fluid to flow in the system until the pressure drops lower than the valve pressure setting.

In the above example, there are two hydraulic actuators for clamp A and B which holds a workpiece. A pressure relief valve. A pressure reducing valve. And a direction control valve and positive displacement pump. The pressure relief valve setting is 300 bar. So, the maximum system pressure is 300 bar. When the direction control valve is in the first position both the clamp cylinders extend but in clamp A the pressure will be maximum as system pressure but in clamp B due to the pressure reducing valve setting, the pressure will be 200 bar. As soon as the pressure increases in the clamp B line the pressure reducing valve will close and not allow the pressurized fluid to flow. Hence, the pressure will limit at 200 bar.

For better understanding, you may read click here this article.

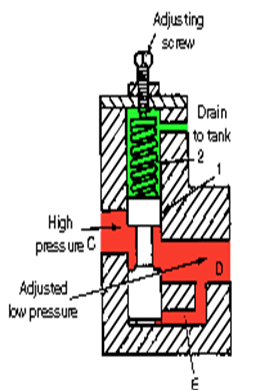

Construction of pressure reducing valve

A common pressure reducing valve consists of an inlet port (C), an outlet port (D), and a pilot line (E). There is a spool against the spring tension which opens and closes the path for pressurized fluid. As the pressure increase at the outlet port (D) beyond the spring tension (i.e. Pressure setting), pilot line (E) shift the spool against the spring and make the opening narrow. Due to the

FAQ about pressure relief valve and pressure reducing valve

- What exactly happens if the pressure relief valve replaced by a reducing valve?

Answer: The function of a pressure relief valve is to limit the maximum pressure in a hydraulic system. It closes normally and opens only when the system pressure exceeds the setting of the pressure relief valve, by releasing pressurized oil to the lower pressure side or tank. Whereas on the other hand, the pressure reducing valve limits the pressure for the system to less than the maximum pressure. It opens normally and closes only when the system pressure at the output of the reducing valve exceeds its set pressure. But if we replace a pressure relief valve with a pressure reducing valve, the required pressure cannot be generated. Because there is no longer the necessary restriction to generate pressure and the flow will be directed to the tank due to their constructional difference. For more understanding Read hydraulic symbols.

Hope, you like this article and learned the basic of pressure relief valve and pressure reducing valve.

Hello,

Kindly provide us your best price for the following item;

Enerpac Hydraulic Pump -10,000psi———-40 pieces

Looking forward to doing business with your company

Thank you.

Sincerely yours,

Esther Zimmerman

Director, Purchase & Strategic Sourcing

CVS Health Corporation

One CVS Drive

Woonsocket, Rhode Island 02895