Last updated: July 12, 2020

Annealing and tempering are both heat treatment processes. It improves some properties of metals and alloys. But there is a fundamental difference between them. Here we will try to find the answer to a very common question that which heat treatment process used for softening hardened steel?

Process of Heat Treatment

Before understanding the basic difference between annealing and tempering, one has to understand the general process of heat treatment. The heat treatment can complete in the following 3 steps.

- Heating a metal (or alloy) at a specific temperature.

- Holding a metal (or alloy) at an increased temperature for a specified period.

- The cooling of the metal (or alloy) according to the specified process and medium.

These three phases will determine the heat treatment process and improve some mechanical properties in the metal or alloy.

Annealing Vs Tempering

Annealing and Tempering, both are used mostly for softening the steel. But both are the two different methods of heat treatment. Let’s have a look at their objectives.

The main objectives of Annealing are:

- Soften the metal, so that metal can be cold worked or easily machined.

- Refine the grain structure and its size in order to increase strength and ductility.

- Relief the internal stress which may be caused by hot or cold work.

- Altering the magnetic, electrical, and physical properties.

- Remove the trapped gas in metal during casting.

The main objectives of Tempering are:

- Reduce the brittleness of already hardened steel.

- Increase the ductility and toughness of hardened steel.

- Reduce the hardness of hardened steel and make it soft.

- Relief the internal stress which may be caused by the rapid cooling of steel during quenching.

Annealing

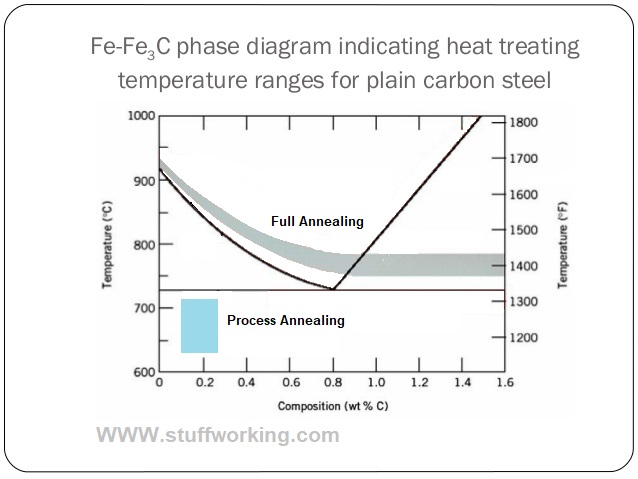

In the annealing process, steel is heated above the recrystallization temperature. Hold the steel for some time and then slowly cooled. Annealing can also be categorized as Full Annealing and Process Annealing.

Full Annealing Heat treatment process:

The main objective of the full annealing process is to:

- soften the metal

- refine its grain to increase ductility

- relieve internal stresses.

- remove trapped gases in the metal

The process consists of heating the steel at about 50°C above the upper critical temperature for hypo-eutectoid steel and 50°C above the low critical point for hyper-eutectoid steel. Then keep the steel at this temperature for sufficient time, So that all the steel transforms into austenite or austenite-cementite. It is then allowed to cool in the furnace for some time. The cooling rate can range from 20°C to 200°C per hour depending on the steel and desired properties.

Process Annealing Heat Treatment process

The main objective of the process annealing is to:

- relieve internal stresses.

- Increase the Machinability of steel.

- Softening of low carbon steel for cold work

Process annealing generally for low carbon steel(< 0.25% Carbon) which is work hardened. For this process, low carbon steel is heated close to the lower critical temperature (below the ferrite-austenite region).

This is held long enough to permit recrystallization of the ferrite phase, then cooled in still air. Since the material stays in the same phase throughout the process, the only change that occurs is the shape,

size, and distribution of grain structure.

Tempering

Tempering is a re-heating process subsequent to quench hardening. Quenched hardened steel is very brittle to work. This brittleness can reduce by tempering method.

When the medium carbon steel is heated above the upper critical temperature and sudden (rapidly) cooled in a suitable medium, austenite transforms into martensite. This martensite is very hard and brittle in nature. Also, it is a somewhat unstable structure. That is why tempering is done immediately after quenching (when steel cools down about 40°C).

In the tempering process, quenched hardened steel is heated below the lower critical temperature. At 200°C to 250°C, the internal stress will be removed and the ductility will increase without changing the structure of the martensite and without compromising the hardness of the steel.

At 300°C to 400°C, a softer and tougher structure troostite will form. This troostite is responsible for reducing the hardness. Above 400°C martensite begins to change into sorbite and completely changes at 700°C. Sorbite is much softer and less strength than troostite but it increases ductility.

Up to 350°C, mineral oil is best for tempering. Above 350°C, the liquid salt bath (a mixture of nitrate and nitrites) are preferred. It is very important to heat the steel gradually to avoid cracking. After heating to the desired temperature, the steel has to hold at this temperature for some time (depending on the dimensions and structure of the steel) and then cooled in still air.

So, tempering is performed on hardened steel for the desired combination of hardness, strength, ductility, toughness, and structural stability. Now, decide yourself, which heat treatment process used for softening hardened steel? Comment Below.

Read the book Material Science by R.S Khurmi for more knowledge.