Last updated: October 2, 2020

The basic function of a Gear coupling is to provide a mechanical connection between two rotating shafts. They use gear mesh for transmitting power and torque between the connected shafts. Hence, gear Coupling is a mechanical device that transmits torque between two shafts by using gears.

A gear coupling is very much considered a flexible coupling. It can transmit torque between two shafts that are not collinear or which have some misalignment.

The function of a Gear coupling to be a positive torque transmission coupling. It is suitable for horizontal assembly. However, the specially designed gear couplings are available for vertical assembly too. Moreover, It provides high torsional stiffness due to gears and therefore it is torsionally rigid coupling. Generally, the gear ratio is 1:1.

Type of gear coupling

Mostly there are two types of gear coupling in uses.

- Flexible-flexible coupling (or flexible gear coupling).

- Flexible-rigid coupling (or semi-flexible coupling).

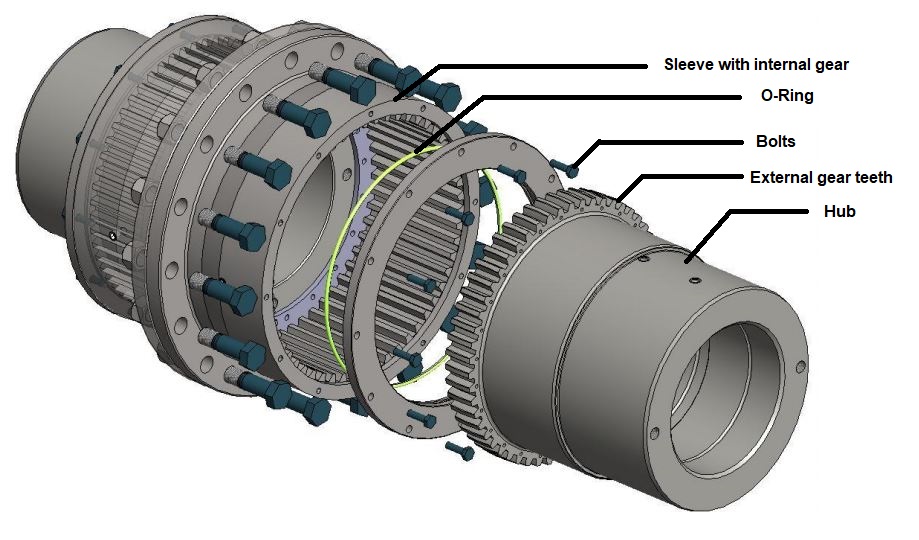

Flexible Gear coupling: It consists of two hubs with external gears and two sleeves with internal gears. Both the hubs and sleeves are coupled with gear mesh and bolted with bolts.

A flexible gear coupling can use for all sort of application & accommodates all possible misalignments (angular, offset, axial or combination of all).

So, there is no additional force on machines, bearings, seals and shafts.

Semi-Flexible gear coupling: It consists of one flexible half likewise flexible coupling but another half will be fixed like flange coupling. And both the half will be coupled together with bolts.

Wherever there is less chance of misalignment one can use semi-flexible gear coupling. Thus, he can reduce the cost. Particularly Minimizing the misalignment means maximizing the life of coupling, machines, bearing, seals and shafts.

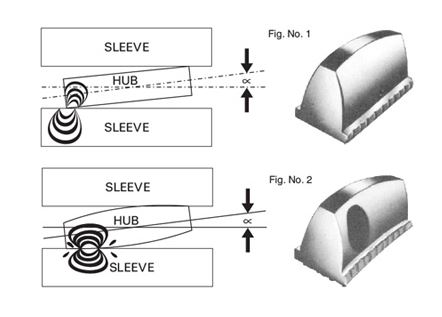

Specially designed gear teeth

If the teeth of gears are simply straight, there will be more wear and tear on gear profile. Because under misalignment condition the teeth contacts will be minimum. And also there will be excessive play. Because of this play and minimum teeth contact between the hub and sleeve, teeth edge will get damaged and reduce the life of the coupling.

Therefore, crown teeth hubs are using instead of straight teeth hubs. Crown teeth have curvature on the flank which increases the contact area between hub and sleeve, reduces edge pressure and hence, increases the life.

Following are the points to remember during installation.

Some gear coupling does not get a chance at a decent life due to their installation.

Hub and Sleeve: Higher speed application should have adequate interference fit to offset centrifugal force effects on the shaft. But If the contact pressure between the shaft and hub is excessive due to the interference fit, it may lead to hub failure.

Key and keyways fit: Keyways should have a proper radius to reduce the risk of fatigue cracking. Also, the key length should be measured to minimize coupling imbalance.

Hub bore: Ensure hub bore must be concentric to minimize hub run-out.

Hub installation: Choose proper heating method so that the hub’s material properties do not compromise. Also, take care of the heating temperature for interference fit so the hub can slide easily over the shaft. Never use the hammer to install or remove the hub as it can damage the gears, bearing etc.

Correct coupling gap: If the floating shafts have a small gap, the shafts may impact each other and get damaged.

Proper sealing: Ensure proper gasket and O-ring to retain the lubricants in the coupling.

Alignment: Alignment for the components must be within the limit.

Maintenance

Lubrication is the only main part of maintenance for gear coupling. Lubricants reduce the friction between the teeth as they slide each other. There is relative motion between teeth due to misalignment. This motion is oscillatory, low amplitude and high in frequency. This causes wear and tear and heat generation. But with the good lubrication, it can minimize.

Generally, the manufacturer recommends regreasing in every 12 months but completely depends on the uses and condition. Hand packing method is used for regreasing in annual maintenance.

This is all about the function of a gear coupling.

Thank You