Last updated: May 16, 2020

Pressure reduction valve is a control valve that lowers the inlet pressure of the fluid and gives the desired pressure at the output. The pressure reduction valve maintains a constant pressure in a part of the system that operates at a pressure lower than the normal system pressure. Often we use a variable pressure reduction valve to set it to any desired downstream pressure within its design range. Once the valve is set, it will maintain reduced pressure regardless of changes in supply pressure and system load variations.

Types of Pressure Reduction Valve

There are numerous designs and types of pressure reducing valves. But most common are:

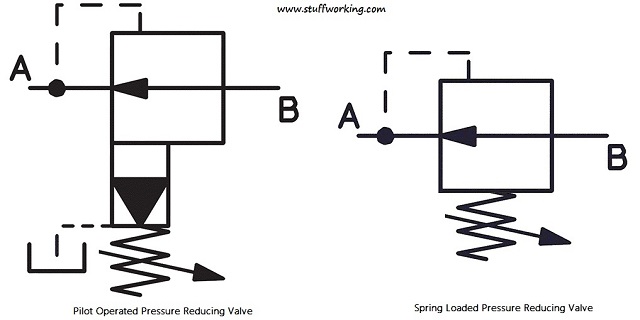

- The spring-loaded pressure reducing valve

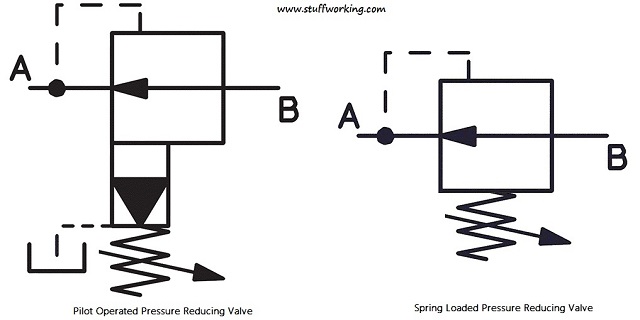

- The pilot-operated pressure reducing valve

Spring Loaded Pressure Reducing Valves

Spring-loaded pressure reducing valve structure and function

The spring-loaded pressure-reducing valve is most commonly used in hydraulic and pneumatic systems. It is generally referred to as a pressure regulator. The valve is normally open all the time. The adjusting spring pressure acts against a diaphragm to open the valve.

When the pressure at the outlet is less than the spring pressure, the spring pressure overcomes the outlet pressure and pulls the valve stem downward. Thus the valve will remain open.

When the outlet pressure is greater than the spring pressure, outlet pressure overcomes the spring pressure and pushes diaphragm and stem upward. Thus the valve will be close.

We can adjust the outlet pressure of the valve by adjusting spring pressure on the diaphragm. Normally, when we turn the adjusting screw clockwise, we are increasing the downstream pressure.

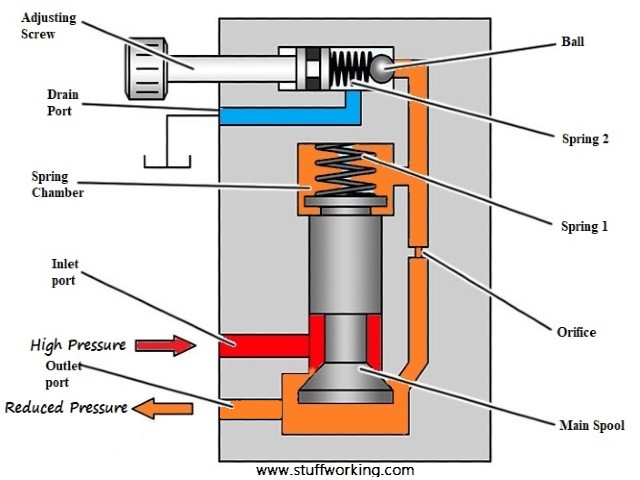

Pilot-Operated Pressure Reducing Valve

The simple diagram above illustrates a pilot operated pressure reducing valve. This valve is similar to the spring-loaded valve in addition to the pilot-controlled valve. High pressure will come from the pump to the inlet port. Normally due to the open condition, the oil will flow to the outlet port. Actually, the pressure at the outlet depends on the spring pressure of the reducing valve.

When pressure builds up at the outlet it will act on the bottom of the main spool. Simultaneously, a pilot pressure acts on the ball against a spring-2 and spring chamber through an orifice. This pressure keeps the main spool open until the pressure at the outlet port is less than the pressure at Spring-2. If the outlet pressure is above the set pressure of spring 2, the ball will move forward and the pilot line will connect with the tank. This will empty the spring chamber and the main spool will move upward and close the inlet port. Thus, a pilot operated pressure reducing valve works.

Pressure reducing valve Symbols